Intermittent Fault Detector™ (IFD-256™) Test Summary

Introduction:

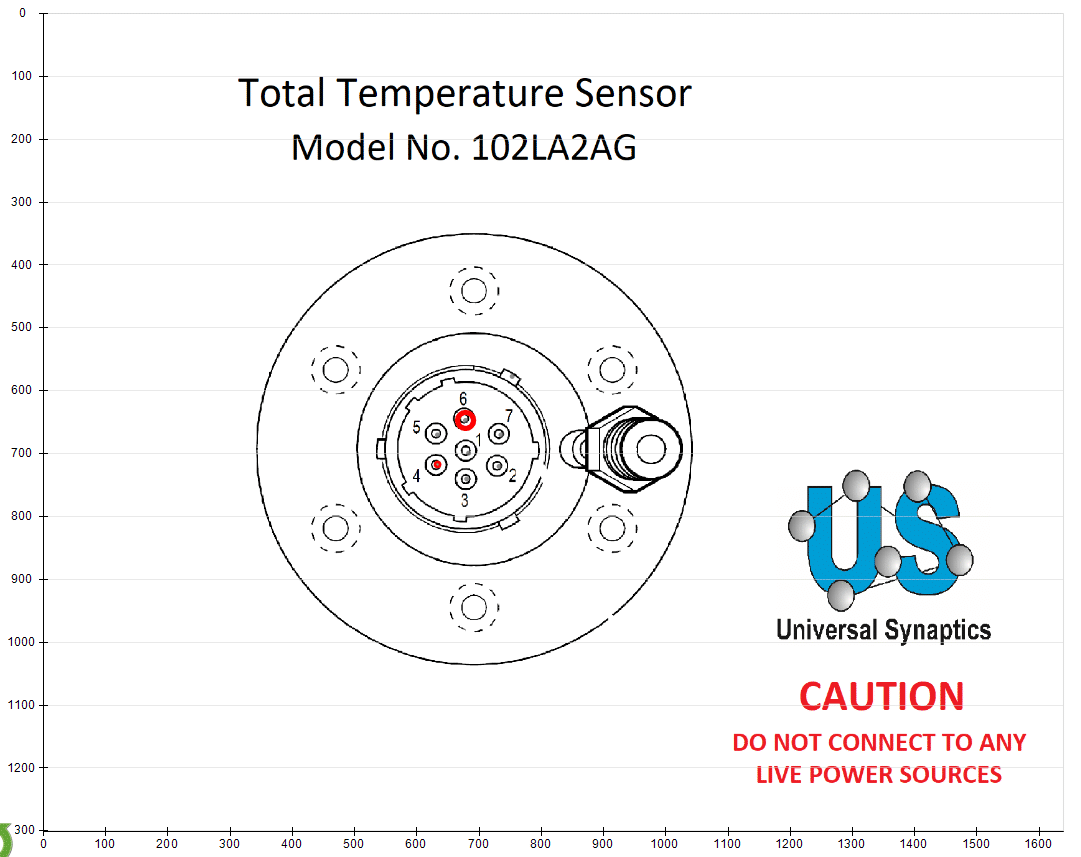

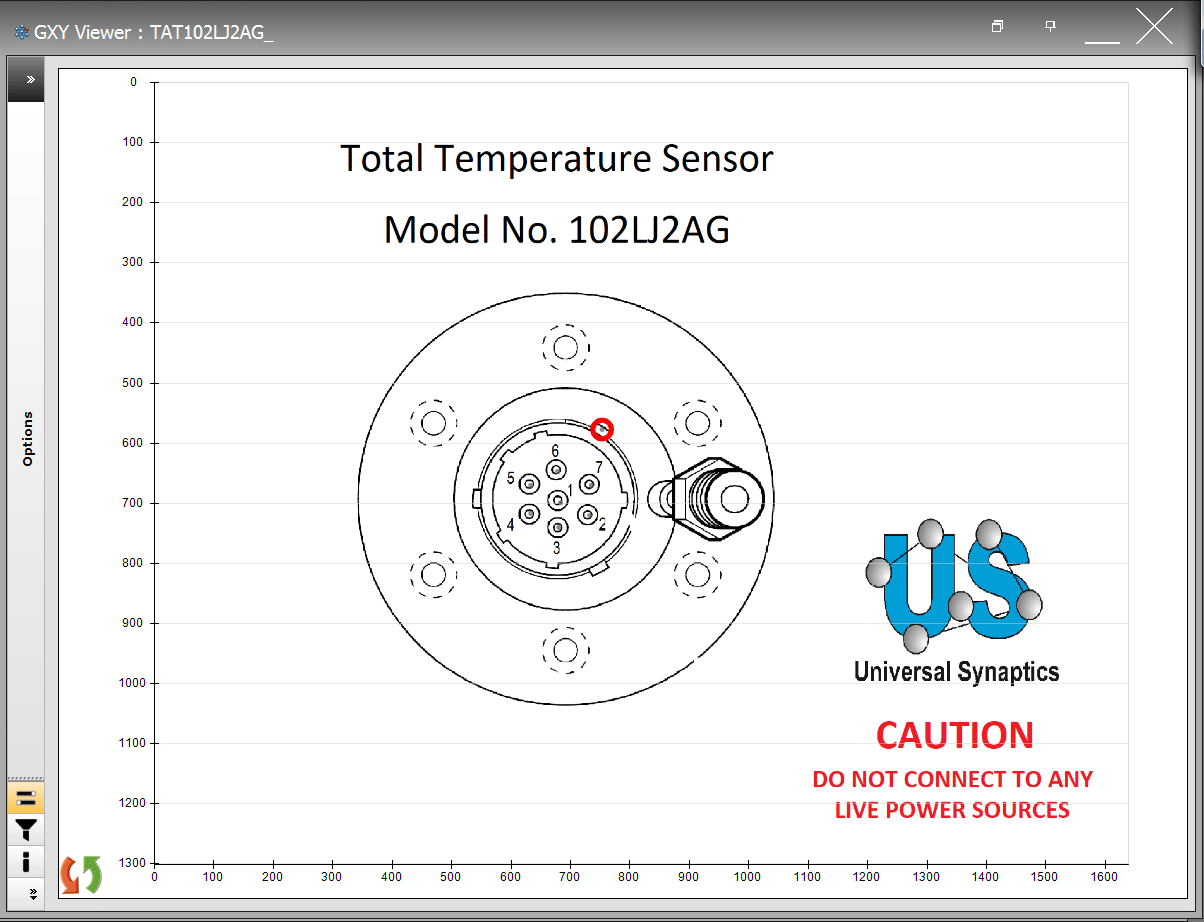

Total Air Temperature (TAT) Probes (P/N 102LA2AG, P/N 102LJ2AG)

S/N: A80547 & S/N: A29936

The listed Total Air Temperature (TAT) Probes were tested at the request of the customer for the purpose of demonstrating the advanced diagnostic capability of the Intermittent Fault Detector™ (IFD™). Universal Synaptics received the TAT Probes on 28 June 2019, testing began on 2 July 2019 using the portable Intermittent Fault Detector (IFD-256™). The Interface Test Adaptor (ITA) was designed and manufactured by Universal Synaptics for this test project.

Test Procedures:

- AutoMap™ – discovered the Unit Under Test (UUT) true as-wired configuration – no OEM data or schematics are required if “Gold” units are provided

- Data was used for this project due to both S/Ns being in non-working condition

- Continuity – tested for open circuits and measures resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provided shorts indication and shorts tracing

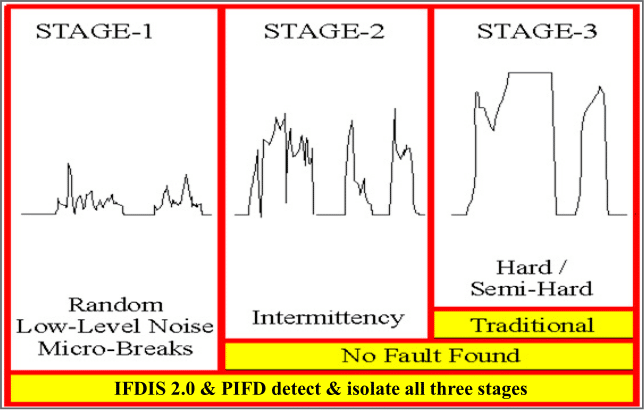

- Intermittence – monitored all circuits to detect and isolate all three Stages of intermittent faults (see Graphic 1)

- Fault Isolation – detected intermittent faults through programmatic isolation

Graphic 1 – Three Stages of an Intermittent Fault

Stage 1 – random low-level nanosecond microbreaks, likely not operationally evident yet, but on curve of degradation to become Stage 2

Stage 2 – intermittent failure evident to pilot in operation, reported to ground crew, passes ground test and labeled No Trouble Found (NTF) or No Fault Found (NFF), on curve of degradation to become Stage 3

Stage 3 – semi-hard or hard failures, Automatic Test Equipment (ATE) and troubleshooting tools such as DMMs designed to detect hard faults (open circuits or shorted circuits)

Results:

S/N A80547

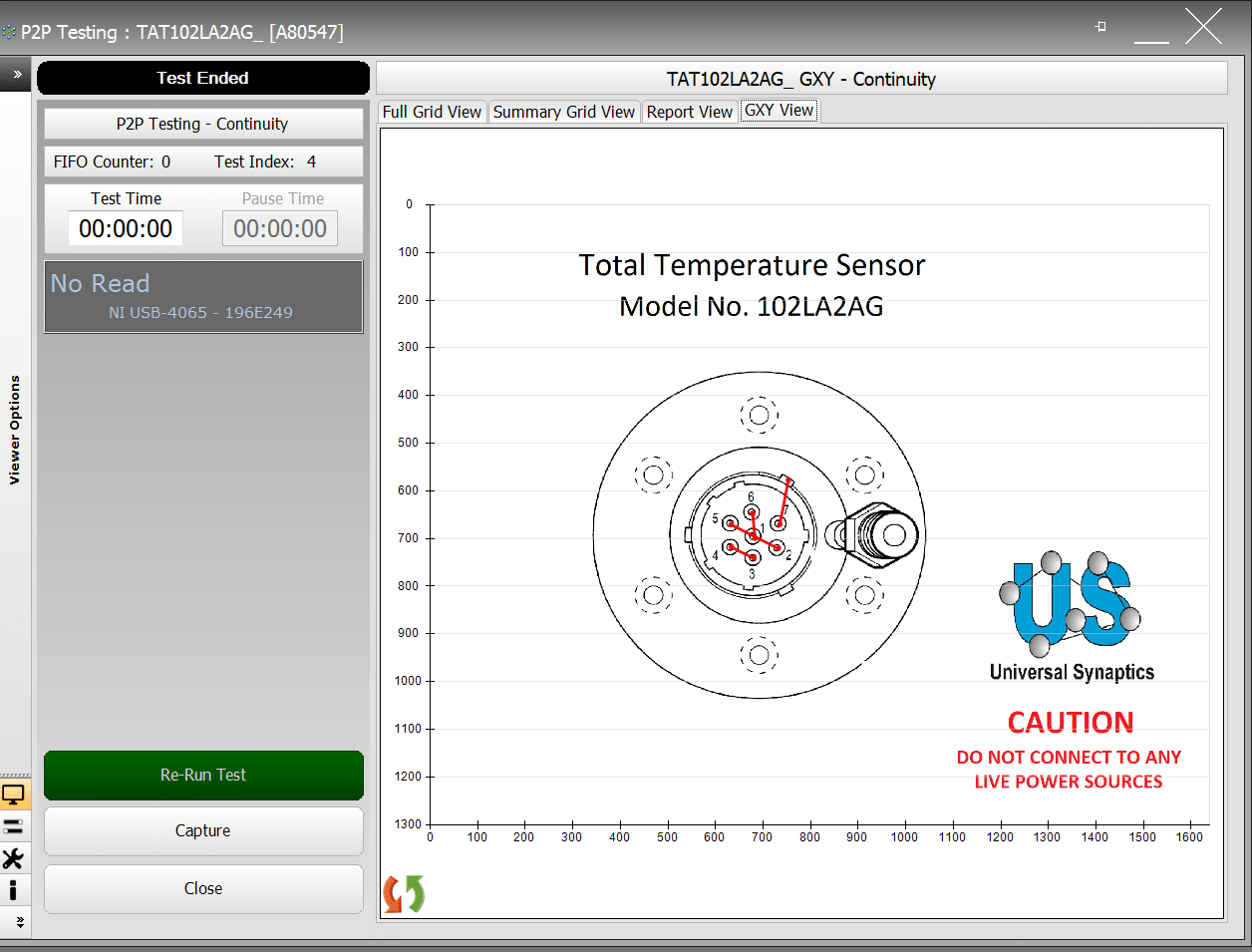

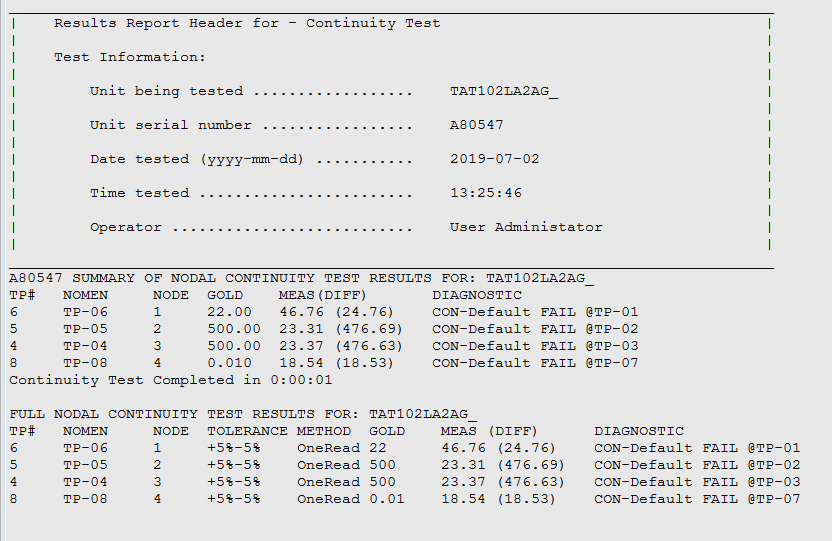

- IFD-256 Continuity testing conducted – test points 4, 5, 6, and shield (TP#8) were outside ohmic measurement tolerances (see Graphics 2 and 3)

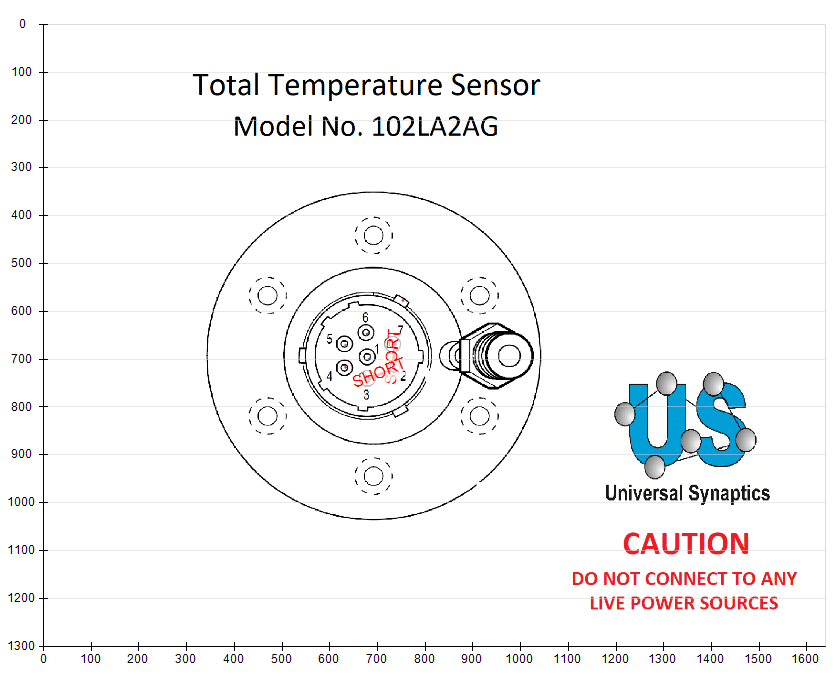

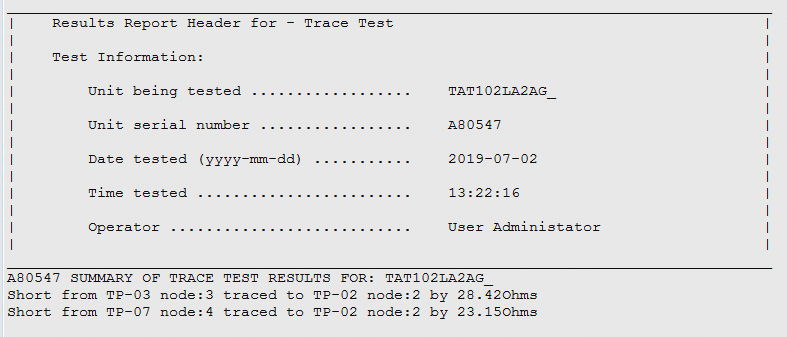

- IFD-256 Shorts testing conducted – shorted circuits were detected on test points 3 and 7 and traced back to test point 2 (see Graphics 4 and 5)

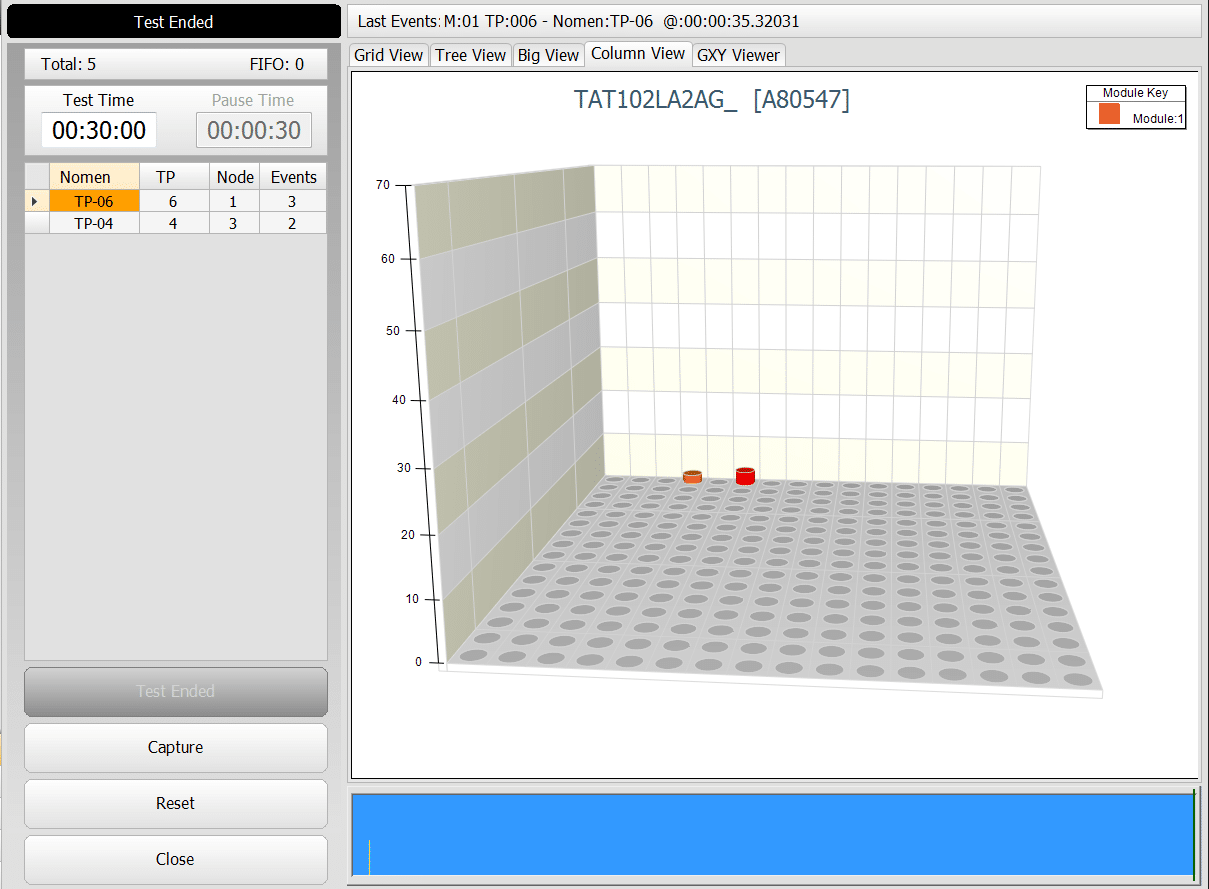

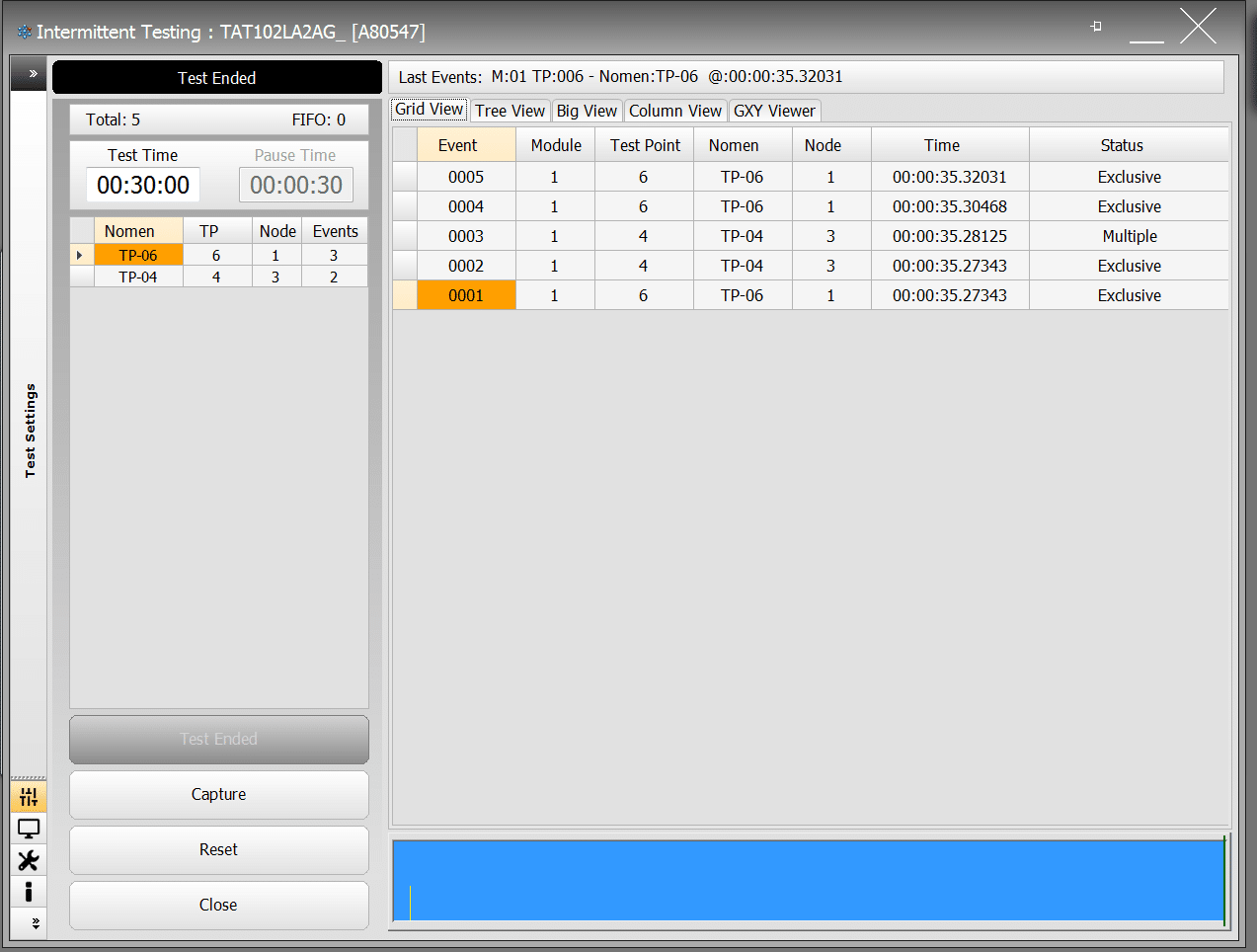

- IFD-256 Intermittence testing conducted – 2 intermittent events detected on test point 4 and 3 intermittent events detected on test point 6 (see Graphics 6, 7, and 8)

Graphic 2 – Continuity Graphic – S/N A80547

Graphic 3 – Continuity Report & Results – S/N A80547

Graphic 4 – Shorts Graphic – S/N A80547

Graphic 5 – Shorts Report & Results – S/N A80547

Graphic 6 – Intermittence Graphic – S/N A80547

Graphic 7 – Intermittence Graphic – S/N A80547

Graphic 8 – Intermittence Grid Graphic – S/N A80547

Results:

S/N A29936

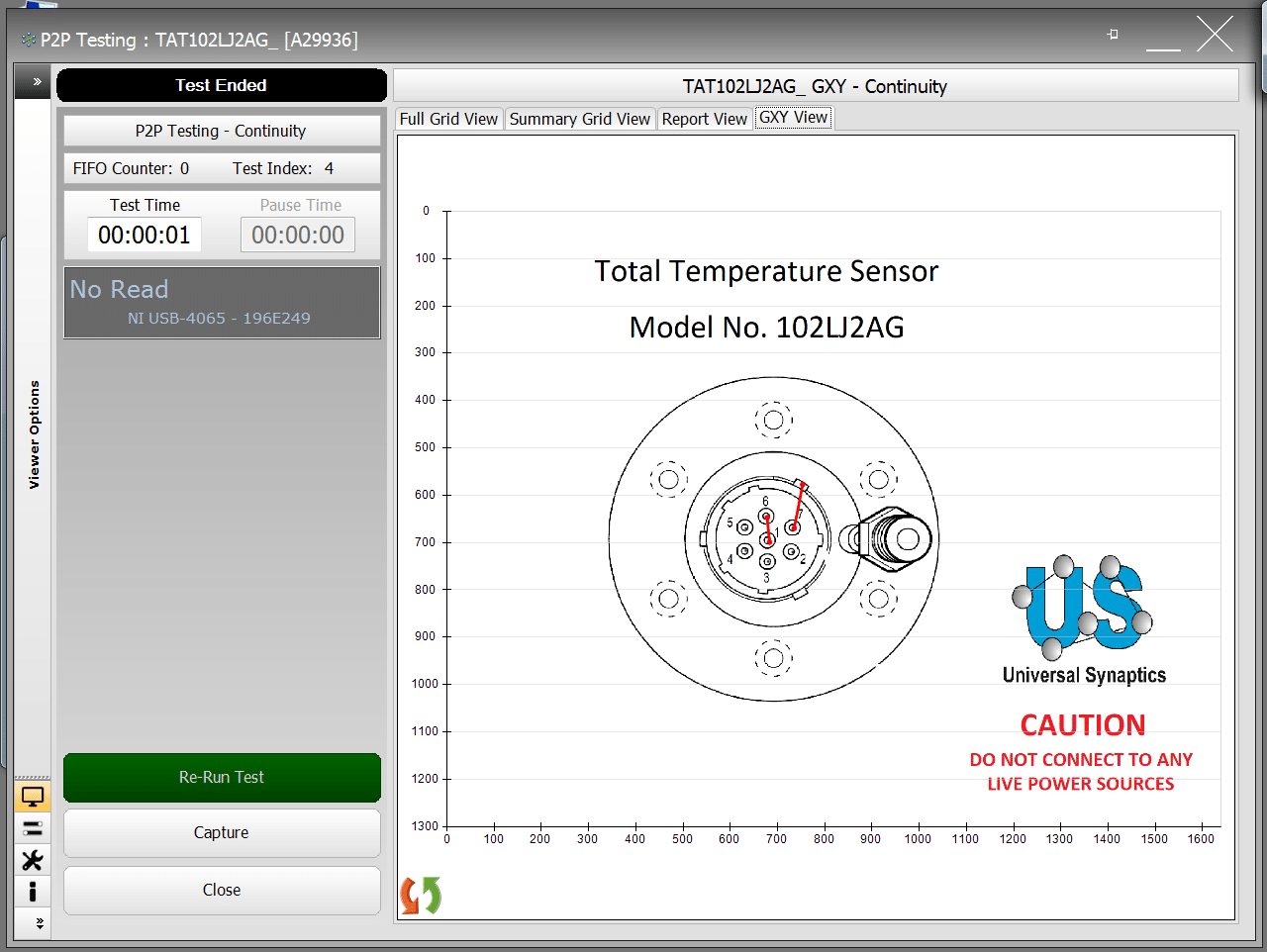

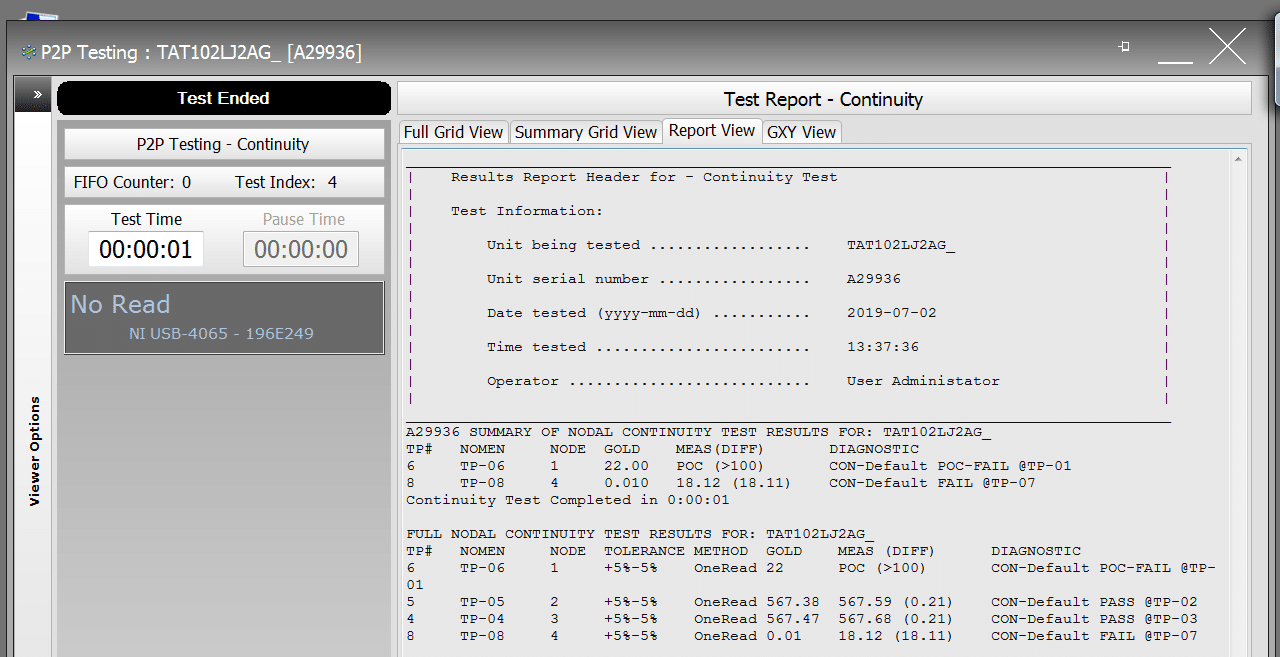

- IFD-256 Continuity testing conducted – test points 6 and shield (TP#8) read open circuit and outside ohmic measurement tolerances, respectively (see Graphics 9 and 10)

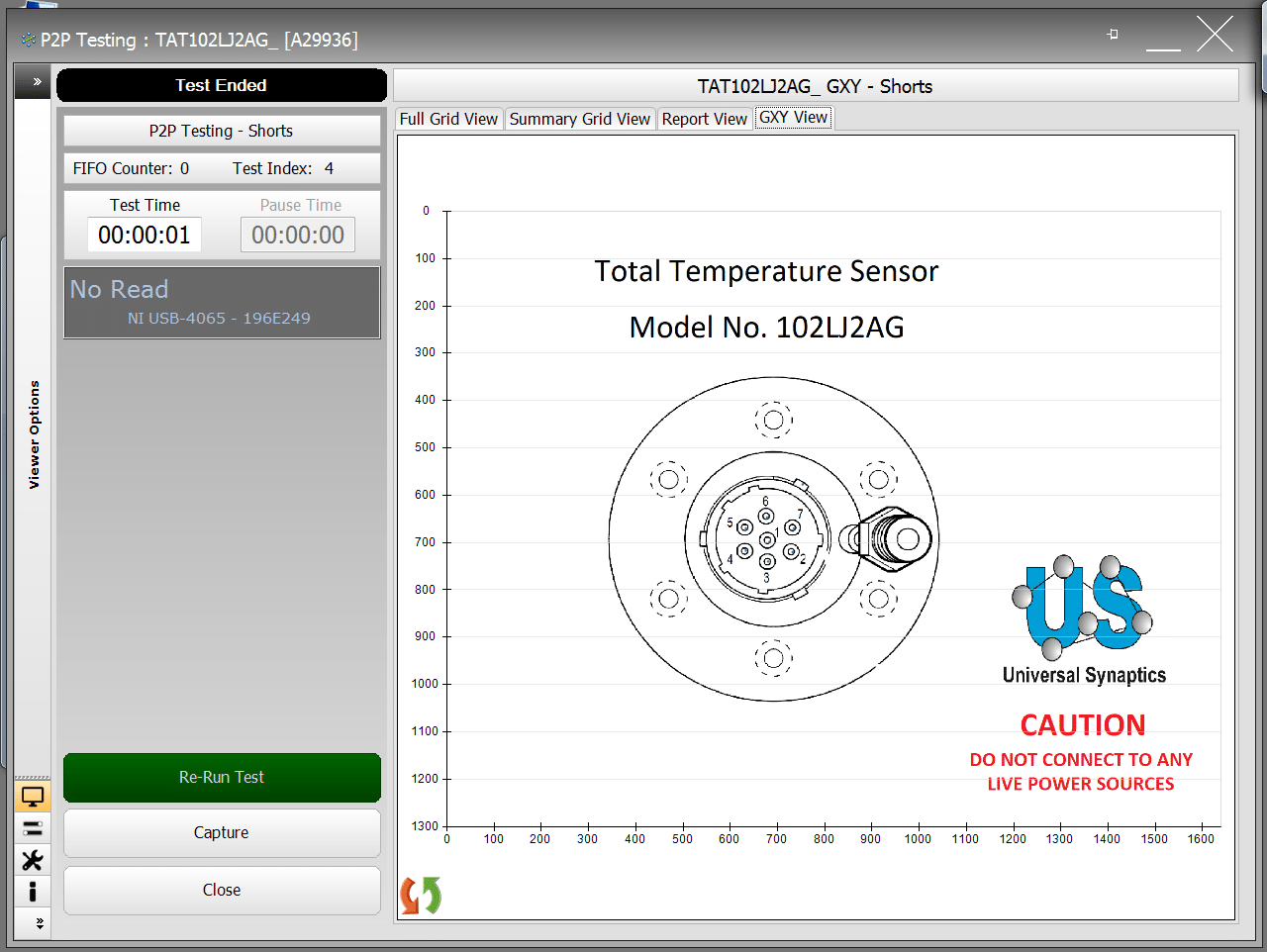

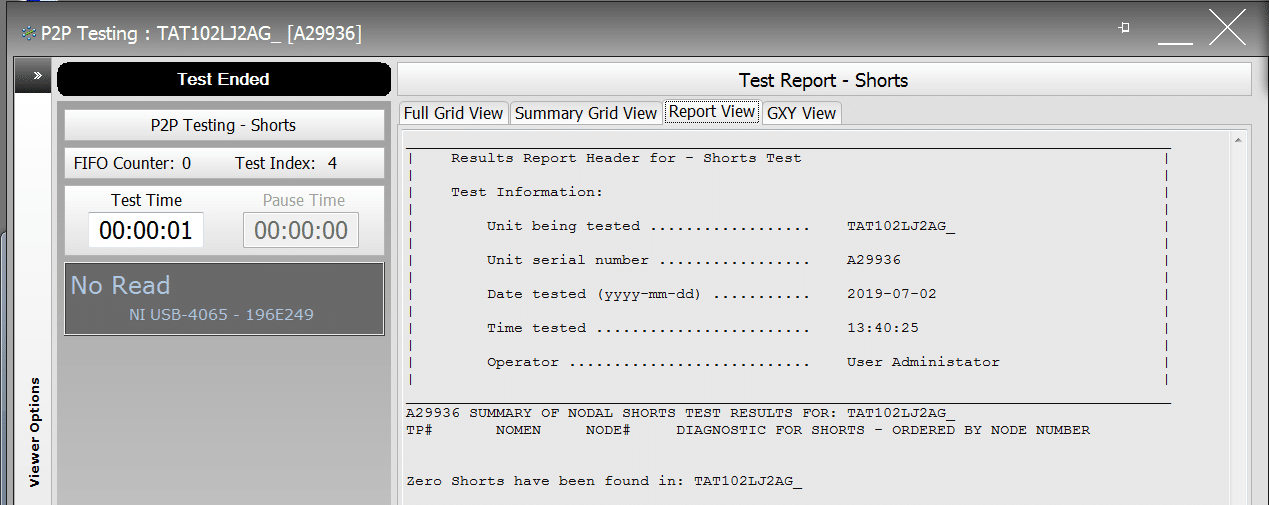

- IFD-256 Shorts testing conducted – no shorted circuits were detected on this UUT (see Graphics 11 and 12)

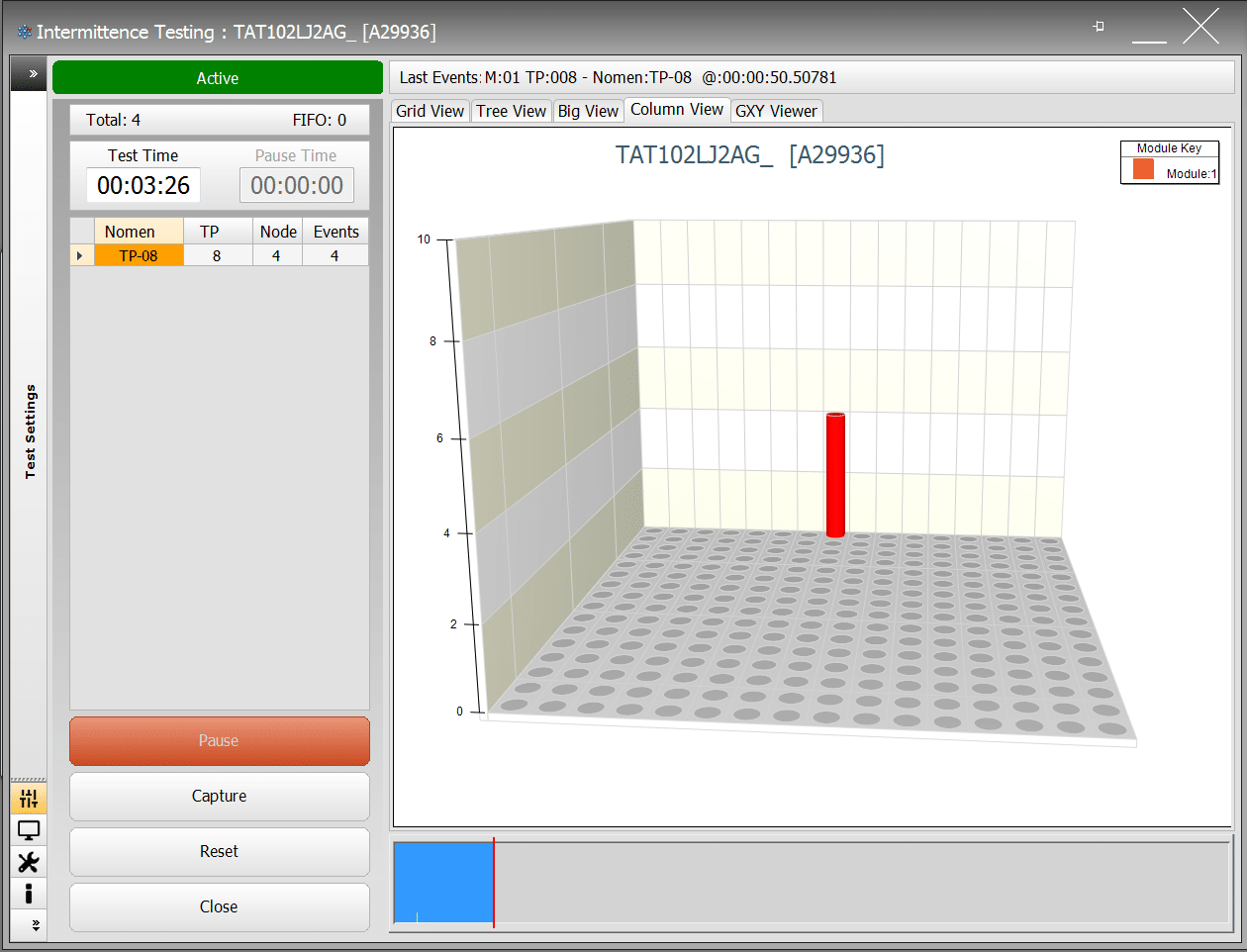

- IFD-256 Intermittence testing conducted – 4 intermittent events detected on shield (TP#8) (see Graphics 13 and 14)

Graphic 9 – Continuity Graphic – S/N A29936

Graphic 10 – Continuity Report & Results – S/N A29936

Graphic 11 – Shorts Graphic – S/N A29936

Graphic 12 – Shorts Report & Results – S/N A29936

Graphic 13 – Intermittence Fault Isolation Graphic – S/N A29936

Graphic 14 – Intermittence Graphic – S/N A29936

Summary:

Universal Synaptics’ patented Intermittent Fault Detection technology has proven to detect and isolate intermittent faults which results in an increase in aircraft component reliability. As proven by this demonstration, the IFD-256 will increase the reliability of the aircraft by ensuring that quality TAT Probes are installed on Delta aircraft, subsequently preventing Operational Difficulty Index (ODI) events and customer dissatisfaction.

S/N: A80547

Delta Air Lines provided details:

- Installed: 12/15/2012

- Removed: 6/9/2019

- Time Since Overhaul (TSO) / Cycles Since Overhaul (CSO): 9,338 FH / 5,061 FC

- No previous removal history

- Believed to be a new probe, not a repaired probe

Continuity, Shorts, and Intermittence tests indicate a catastrophic failure of this probe.

Based on the curve of degradation from a Stage 1 (random low-level micro-breaks) to a Stage 2 (intermittent that causes operational failure) to a Stage 3 (semi-hard or hard broke), this asset was a candidate for IFD testing prior to install

All Stage 3 continuity and shorts found during testing could have likely been manifesting as Stage 1 faults and repaired prior to install, thus extending time-on-wing greater than 9,338 FH

S/N: A29936

Delta Air Lines provided details:

1st Install

- Installed on A/C #6707: 12/15/2015

- Removed from A/C #6707: 3/22/2017

- Reason for removal: proactive replacement of TAT due to trend shift on both engines

- Unit overhauled by CSI: 5/1/2017 (overhauled with latest and greatest Repair Specification)

2nd Install

- Installed on A/C #6717: 6/15/2018

- Removed from A/C #6717: 6/6/2019

- Time Since Overhaul (TSO) / Cycles Since Overhaul (CSO): 3,074 FH / 1,294 FC

- Reason for removal: EICAS message for TAT Probe

- Unit last overhauled: 5/1/2017

Continuity and Intermittence tests indicate a catastrophic failure of this probe.

Based on the curve of degradation from a Stage 1 (random low-level micro-breaks) to a Stage 2 (intermittent that causes operational failure) to a Stage 3 (semi-hard or hard broke), this asset was a candidate for IFD testing prior to install

All Stage 3 continuity and shorts found during testing could have likely been manifesting as Stage 1 or 2 faults and repaired prior to install, thus extending time-on-wing greater than 3,074 FH

Image 1 – Total Air Temperature Probes S/N: A80547 and S/N: A29936