Portable Intermittent Fault Detector™ (PIFD-512™) Test Summary

Introduction:

The Lockheed Martin (LM) / Universal Synaptics (USC) Team performed PIFD testing on the F-16 wing AWTS Interface Test Adapters (ITAs) and F-16 wiring harnesses at utilizing the following equipment:

- Portable Intermittent Fault Detector™ (PIFD™) the test was conducted with a 512 version of the test set

- NSN: 6625-01-696-1235

- Four PIFD to AWTS Interface Test Adapters (ITAs) patch cables to electrically connect the PIFD to the AWTS interface adapters and the F-16 wing wiring harnesses

- A handheld vibration tool to stimulate the wiring harnesses during PIFD testing

Location:

- REDACTED, Bldg. REDACTED hangar bay

Background:

The F-16 wing wiring harnesses were selected by the F-16 wing maintenance leadership team due to workload requirements. Conventional single-circuit scanning test equipment and troubleshooting methods are too slow based on workload demand. The MBFI test team is looking for methods to supplement its test capabilities.

The use of PIFD will significantly reduce the time to troubleshoot wiring discrepancies. Conventional test equipment was developed to find open circuits and short circuits in a static environment. The PIFD has these conventional test capabilities, however, the PIFD is the only objectively Wiring Test Set proven to reliably detect and isolate intermittent faults.

Testing was conducted in situ. USC and LM arrived with the PIFD test set, AWTS patch cables, and a handheld vibration tool. No tech pubs, wiring schematics, or other maintenance or aircraft wing data was provided to the LM / USC team. No Test Program Set (TPS) or AutoMap™ was developed before arrival on 27 February 2024 to demonstrate the PIFDs AutoMap™ capability, ease of use with minimal training, and advanced diagnostic capability.

Test Procedures:

- AutoMap™ – discovered the F-16 wiring harness as-wired configuration

- Continuity – tested for open circuits and measures resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provided shorts indication and shorts tracing

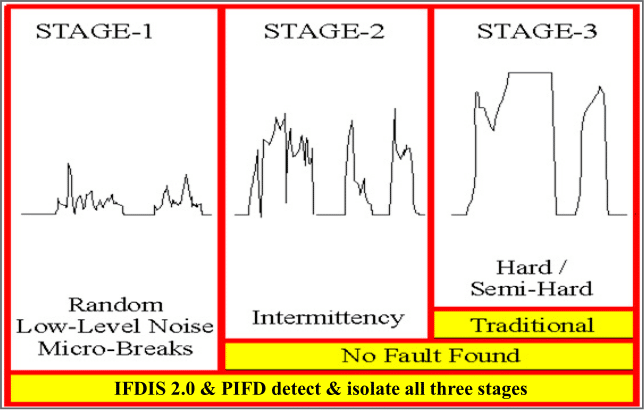

- Intermittence – monitored all circuits to detect and isolate all three Stages of intermittent faults (see Graphic 1)

- Fault Isolation – detected intermittent faults through programmatic isolation

Graphic 1 – Three Stages of an Intermittent Fault

Stage 1 – random low-level nanosecond microbreaks, likely not operationally evident yet, but on curve of degradation to become Stage 2

Stage 2 – intermittent failure evident to pilot in operation, reported to ground crew, passes ground test and labeled No Trouble Found (NTF) or No Fault Found (NFF), on curve of degradation to become Stage 3

Stage 3 – semi-hard or hard failures, Automatic Test Equipment (ATE) and troubleshooting tools such as DMMs designed to detect hard faults (open circuits or shorted circuits)

Test Process:

- AutoMap™ – discovered the as-wired configuration of the F-16 wing wiring harnesses. This step took nine minutes to complete. No information was entered into the PIFD to demonstrate the time savings provided by utilizing AutoMap’s’ artificial intelligence, and machine learning process.

- Continuity – tested for open circuits and measures resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provided shorts indication and shorts tracing

- Intermittence – monitored all circuits to detect and isolate intermittent faults

- Fault Isolation – programmatic isolation of detected intermittent faults

Results: F-16 Wing Wiring Harness

Test #1:

- Automap discovered 159 wired connections, with 92 Node groups

- Continuity testing conducted – two open circuits present in the AWTS test adapter wire harness – these open circuits were known to the team at REDACTED AFB

- Shorts testing conducted – no short circuits were present.

- Intermittence testing conducted – light vibration was applied via a handheld vibration tool. Utilizing the vibration tool at the AWTS interface cable connection to the PIFD AWTS patch cable several intermittent faults were detected and isolated in the AWTS interface cables.

- Intermittent faults were detected at J10-P13 (23 intermittent events), J05-P44 (two intermittent events), J-05-P11 (two intermittent events), and J11-P44 (one intermittent event)

- The intermittent faults that were detected and isolated in the AWTS interface cables were documented

Test #2:

After documenting the intermittent faults in the AWTS interface cables (identified above in Test #1), testing continued to the F-16 wing wiring harnesses.

- Continuity testing conducted – two open circuits were detected (J07-P34 to J01-P01 and J11-P44 to J01-P01).

- Shorts testing conducted – PASSED.

- Intermittence testing conducted – intermittent faults were detected and isolated on:

- J11-P48 – 50 intermittent events

- J07-P34 – 50 intermittent events

- J05-P11 – 50 intermittent events

- J03-P44 – four intermittent events

- J10-P13 – 50 intermittent events

- J10-P03 – 50 intermittent events

- J11-P44 – 50 intermittent events

- J05-P02 – 22 intermittent events

- J09-P34 – 18 intermittent events

- J05-P44 – six intermittent events

- J10-P23 – 50 intermittent events

- J09-P42 – 50 intermittent events

- J10-P28 – one intermittent event

- J10-P34 – 50 intermittent events

- J07-P42 – one intermittent event

- J05-P43 – one intermittent event

- J11-P01 – 11 intermittent events

- J07-P35 – three intermittent events

- J03-P36 – seven intermittent events

- J09-P38 – two intermittent events

- J10-P43 – 50 intermittent events

- J07-P18 – four intermittent events

- J08-P38 – 13 intermittent events

- Fault Isolation conducted – intermittent faults taken to root cause on REDACTED AFB selected intermittent failures. The REDACTED AFB, LM, USC Team did not take all intermittent faults to root cause based on this no-cost technology demonstration for the USAF. All PIFD test reports will be provided to the REDACTED AFB Team.

One additional PIFD test was conducted with the same results as noted above. The REDACTED AFB Team was satisfied with the performance of the PIFD and requested additional documentation and test reports. Those documents and test reports have been provided to the REDACTED AFB Team.

Observations:

- Conventional single-circuit scanning test sets, digital multi-meters, and functional ATE are limited to a single circuit measurement and were not designed to detect or isolate intermittent faults that are regularly detected and isolated by the PIFD.

- The LM / USC team’s collaboration with the REDACTED AFB Team contributed to the overall success of the PIFD technology demonstration.

- This project kicked off on 23 February 2024, resulting in a collaborative exchange of how the PIFD AWTS patch cables could be leveraged to demonstrate the advanced capability of the PIFD with no new interface cable manufacturing or hard-coded test program set (TPS) development requirements to utilize the PIFD.

- The REDACTED AFB, LM, and USC teams began the testing project at 0915, AutoMapped, tested, documented results, and retested completing all test tasks at 1115.

Summary and Recommendation:

Universal Synaptics’ patented Intermittent Fault Detection technology has been proven to increase aircraft availability and reliability. As proven by this demonstration, the PIFD once implemented will increase the efficiency of the testing process for the F-16 wing wiring project, and the reliability of the F-16 wings. Once connected to the aircraft fuselage wiring systems the PIFD will ensure that open circuits, shorted circuits, mis-wires, and intermittent circuits have been identified and repaired before wings are reconnection to the main fuselage in the F-16 Service Life Extension Program.

The ability to detect and isolate intermittent faults in wiring harnesses and resolve problems instead of No Fault Found (NFF) test scenarios will improve the REDACTED AFB Team’s ability to deliver F-16 wings on time with greater reliability. This outcome will increase the efficiency of the program and complement the MBFI test team’s efforts while saving the USAF unnecessary expenses associated with troubleshooting wiring harnesses with conventional test methods and equipment. Reductions in NFF, root cause failure data, increased test efficiency, and accurate repair have been proven to significantly increase aircraft readiness in every instance where the PIFD has been applied.