Portable Intermittent Fault Detector™ (PIFD-512™) Test Summary

C-130 EIDS Cable Harness

Introduction:

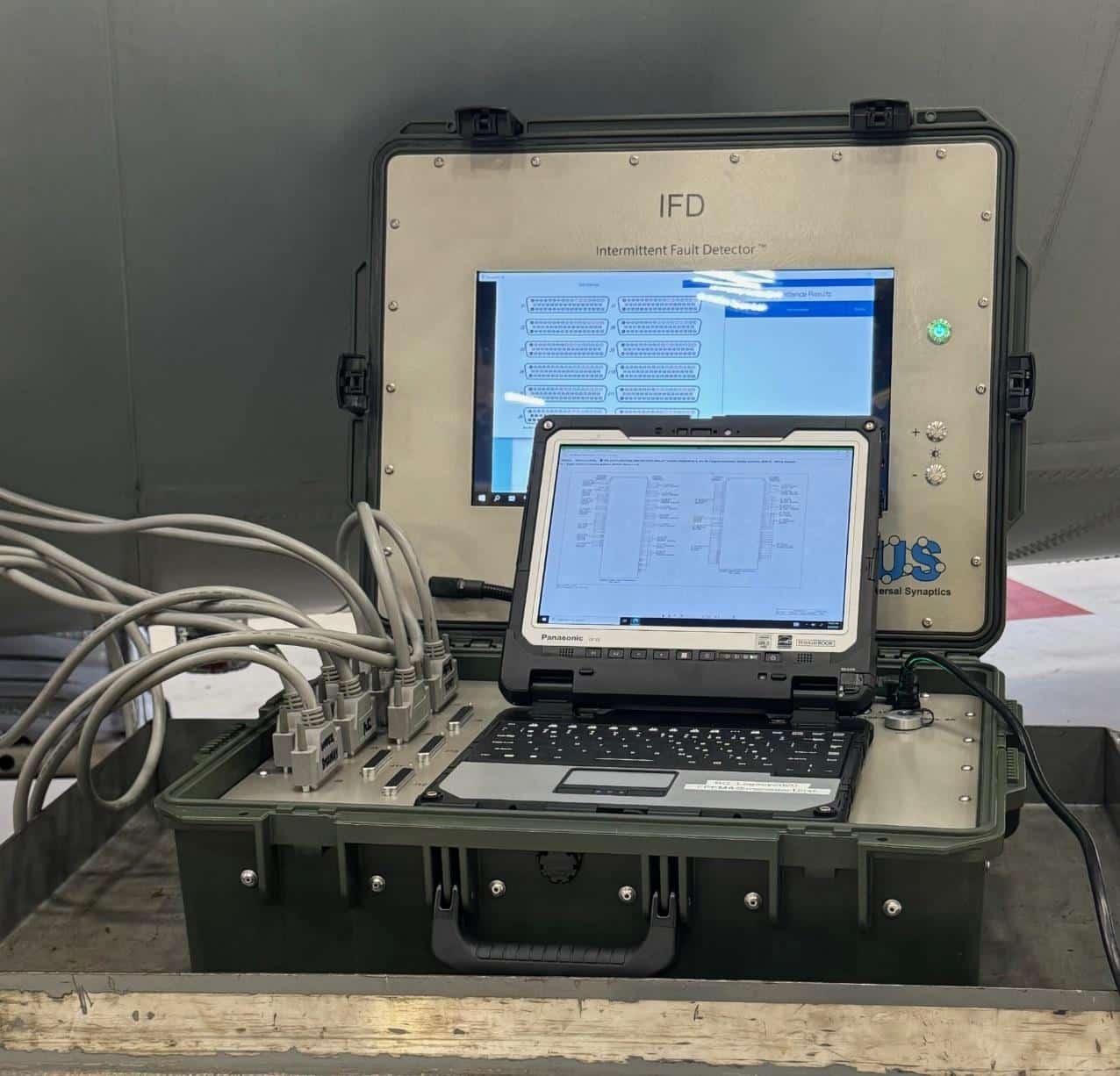

The Lockheed Martin (LM) / Universal Synaptics (USC) Team performed testing on the C-130 Engine Instrument Display System (EIDS) wiring harnesses at NAS REDACTED utilizing the following equipment:

- Portable Intermittent Fault Detector™ (PIFD™) – test was conducted with a 512 test point version of the PIFD

- NSN:6625-01-696-1235

- Six PIFD Interface Test Adapters (ITAs) to electrically connect the PIFD to the EIDS wiring harnesses

- Handheld vibration tool to stimulate the wiring harnesses during PIFD testing

Location:

- NAS REDACTED Fleet Readiness Center REDACTED, REDACTED hangar bay

Background:

The C-130 (tail number REDACTED) Engine Instrument Display System (EIDS) wiring harness was selected by REDACTED leadership due to repeated intermittent functionality complaints during flight operations. REDACTED maintenance teams have been chasing this problem for the last 18 months. Conventional single-circuit test equipment and troubleshooting methods have been proven insufficient by maintenance teams to remediate this long-standing A-799 cannot duplicate (CND) issue. The aircraft regularly passes ground tests but continues to fail during flight operations.

Tail number REDACTED has experienced 13 operational discrepancies for the Tachometer since January 2024, accumulating 463.2 maintenance man-hours with no root cause determination. The operational discrepancies have remained consistent and documented as “EIDS panel light dims, RPMs fluxed intermittently”, and “Tach fluxes erratically.”

The use of PIFD will significantly reduce the time to troubleshoot in-flight discrepancies once on the ground. Conventional test equipment was developed to find open circuits and short circuits in a static environment. The PIFD has these conventional test capabilities, however, the PIFD is the only objectively proven to reliably detect and isolate intermittent faults.

Testing was conducted in situ. LM and USC arrived with the PIFD test set and vibration tool. LM and USC collaborated with REDACTED over three 15-minute technical interchange telecons to provide instructions on how to manufacture the ITAs for the EIDS. REDACTED had the C-130 EIDS ITA cables manufactured and ready for PIFD aircraft testing upon LM and USC arrival on Monday, 05 Aug 2024. No tech pubs, wiring schematics, or other maintenance or aircraft data was provided to the LM / USC team. No Test Program Set (TPS) or AutoMap™ was developed before arrival onsite to demonstrate the PIFDs AutoMap™ capability, ease of use with minimal training, and advanced diagnostic capability.

Test Procedures:

- AutoMap™ – discover the wiring harness as-wired configuration

- Continuity – test for open circuits and measures resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provide shorts indication and shorts tracing

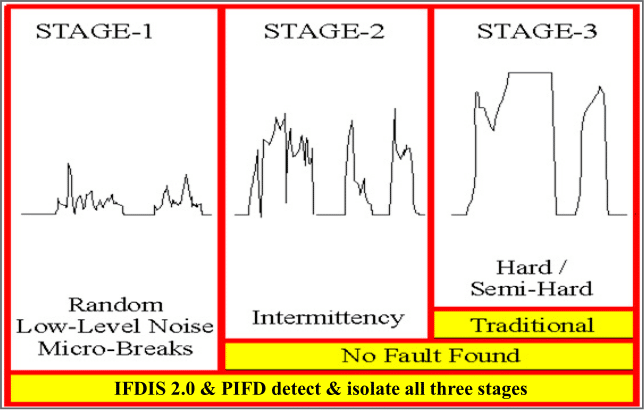

- Intermittence – monitor all circuits to detect and isolate all three Stages of intermittent faults (see Graphic 1)

- Fault Isolation – detect intermittent faults through programmatic isolation

Graphic 1 – Three Stages of an Intermittent Fault

Stage 1 – random low-level nanosecond microbreaks, likely not operationally evident yet, but on curve of degradation to become Stage 2

Stage 2 – intermittent failure evident to pilot in operation, reported to ground crew, passes ground test and labeled No Trouble Found (NTF) or No Fault Found (NFF), on curve of degradation to become Stage 3

Stage 3 – semi-hard or hard failures, Automatic Test Equipment (ATE) and troubleshooting tools such as DMMs designed to detect hard faults (open circuits or shorted circuits)

PIFD Testing the C-130 EIDS

Test Process:

- AutoMap™ – discovered the as-wired configuration of the wiring harness. This step took approximately four minutes to complete. The EIDS is comprised of 191 wires with 41 node groups. No information was entered into the PIFD prior to AutoMapping the system to demonstrate the Test Program Set (TPS) time savings provided by utilizing AutoMaps’ artificial intelligence and machine learning process.

- Continuity – tested for open circuits and measures resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provided shorts indication and shorts tracing

- Intermittence – monitored all circuits to detect and isolate intermittent faults

- Fault Isolation – detected and isolated intermittent faults

PIFD Connected to the C-130 EIDS Wiring Harness

Results: C-130 EIDS Wiring Harness

Monday, 4 Aug 2024

Test #1:

- Continuity testing conducted – no open circuits present in the wire harness

- Shorts testing conducted – no short circuits were present

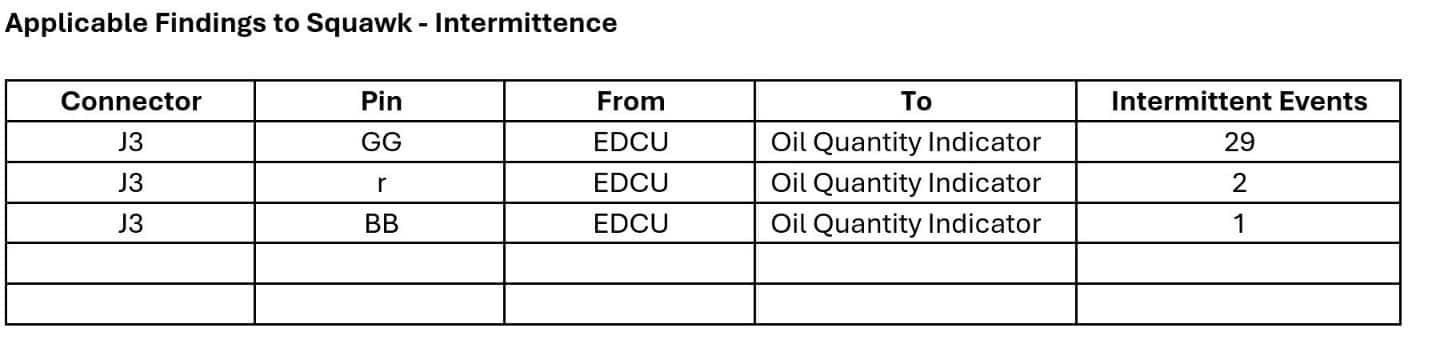

- Intermittence testing conducted – upon walking up the steps into the aircraft to begin troubleshooting the PIFD detected three intermittent events

-

- Intermittent fault detected on J03-P27

- Intermittent fault detected on J03-P01

- Intermittent fault detected on J03-P06

- All intermittent faults located in the wiring for the Oil Quantity Indicator

Testing began at 0850 and concluded at 1030 because of a NAS REDACTED evacuation notice and a tornado warning due to REDACTED.

Tuesday, 5 Aug 2024

Test #2:

REDACTED Maintenance personnel made pin adjustment changes and moved connections on the EIDS ITA before the LM / USC team arrived. It was agreed upon to run a new AutoMap / TPS.

- AutoMap discovered the as-wired configuration of the wiring harness. This step took approx. five minutes to complete. The new configuration of the EIDS ITA discovered 189 wires with 42 node groups.

- Continuity testing conducted – no open circuits present in the wire harness

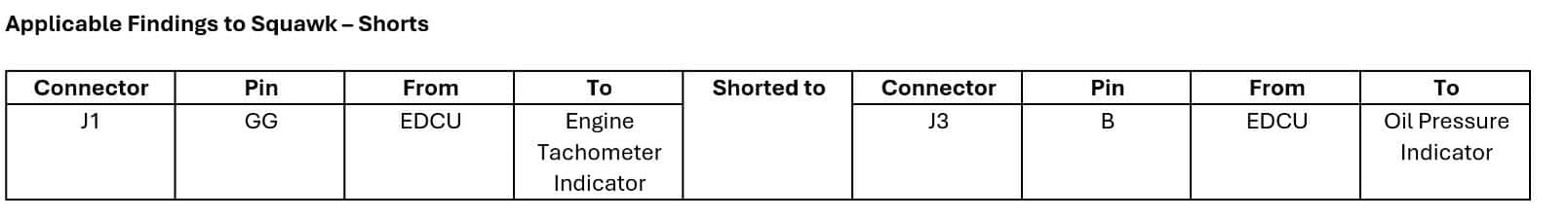

- Shorts testing conducted – intermittent short detected and isolated on the Tach Indicator wire which was shorted to the Oil Quantity Indicator wire. The Oil Quantity Indicator had intermittent opens detected and isolated by the PIFD on Monday, 04 Aug 2024 – see Test #1 above.

- Intermittence testing conducted – several intermittent faults were detected and isolated:

Applicable Findings to Squawk – Intermittence

Applicable Findings to Squawk – Shorts

PIFD Test Screen displays exact pins and locations where Tach and Oil Indicator wire indicated intermittent faults, confirmed and taken to root cause with schematics

Cockpit location of wire harness and location of detected and isolated intermittent wires. Intermittent Wires located next to mounting clip.

Observations:

- Conventional single circuit scanning test sets, digital multi-meters, meggers, TDR, and functional ATE are limited and were not designed to detect or isolate intermittent faults that are reliably detected and isolated by the PIFD

- The LM / USC team collaboration with REDACTED and C-130 FSTs from Fleet Readiness Center REDACTED contributed to the overall success of the PIFD technology demonstration which took this long-standing maintenance issue to the root cause to enable surgical repair

- REDACTED maintenance personnel with minimal training performed all ITA manufacturing tasks

- REDACTED, LM, USC, and FST teams spent a total of four hours over two days performing AutoMap (artificial intelligence TPS development), testing, validation, and retesting

- REDACTED maintenance teams will begin the surgical repair of the intermittent wires in the coming days – the typical process would include leveraging the PIFD for quality assurance post-repair

- User feedback:

✓ “Easy to hook up and generate a test program set with AutoMap.”

✓ “Having a map of how each aircraft is actually wired will provide massive time savings for troubleshooting and give us the ability to QA aircraft by tail number.”

✓ “This tester will save us a lot of manhours and troubleshooting time.”

✓ “The PIFD is super easy to use, why don’t we have these units across the fleet?”

PIFD Connected to C-130 EIDS for Intermittent Fault Detection

Summary:

Universal Synaptics’ patented Intermittent Fault Detection technology has proven to increase aircraft availability and reliability (GAO-20-116). As proven by this demonstration, the PIFD, once implemented, will increase the reliability of C-130 aircraft wiring systems by ensuring open circuits, shorted circuits, and intermittent circuits are rapidly identified in wiring harnesses installed on C-130 aircraft (breaking the cycle of No Fault Found and A-799 Cannot Duplicate). The PIFD is wholly agnostic and can be utilized on any / all aircraft wiring systems and subsystems.

IFD technology provides the ability to detect and isolate intermittent faults in wiring harnesses and resolve problems instead of No Fault Found (NFF) and A-799 Cannot Duplicate (CND) test scenarios (on tails which are commonly measured in months). The PIFD with AutoMap will save the Navy unnecessary expenses associated with Test Program Set (TPS) development and troubleshooting wiring harnesses with conventional test methods and equipment. Reductions in CND / NFF, root cause failure data, and accurate repair have proven to significantly increase aircraft readiness in every instance where the PIFD has been applied.