Intermittent Fault Detector™ (IFD-256™) Electrical Wiring Interconnection System (EWIS) Test Summary

Introduction:

Test Location: Fort Campbell, KY – Hangar 10

Date: 9 October 2018

Unit Under Test (UUT): AH-64 Apache Black Engine Harness

- Left (Cable ID: W185)

- Right (Cable ID: W186)

Ft. Campbell Current CONOPS:

- Each engine harness costs roughly $11,000

- External damage to harness results in disposal

- Internal cable issues can be repaired but is not done by contracted shop in hangar 10 – they replace with new harness

- QA with conventional / traditional continuity tests (Digital Multi-Meter (DMM)) is the current test procedure for these harnesses

Test Procedures:

- AutoMap™ – discover the Unit Under Test (UUT) true as-wired configuration

- Continuity – test for open circuits and measure resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provide shorts indication and shorts tracing

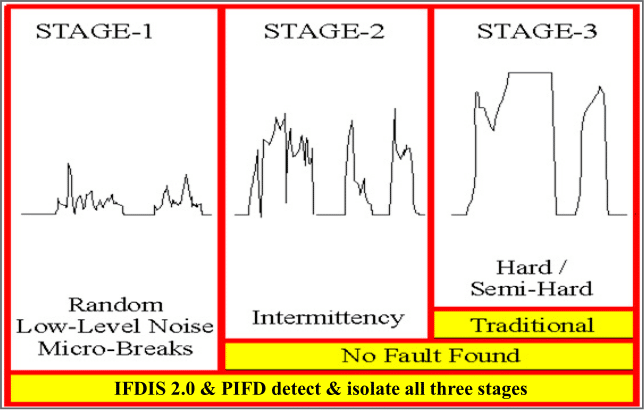

- Intermittence – monitor all circuits to detect and isolate all three Stages of intermittent faults (see Graphic 1)

- Fault Isolation – detect intermittent faults to root cause through programmatic isolation

Graphic 1 – Three Stages of an Intermittent Fault

Stage 1 – random low-level nanosecond microbreaks, likely not operationally evident yet, but on curve of degradation to become Stage 2

Stage 2 – intermittent failure evident to pilot in operation, reported to ground crew, passes ground test and labeled No Trouble Found (NTF) or No Fault Found (NFF), on curve of degradation to become Stage 3

Stage 3 – semi-hard or hard failures, Automatic Test Equipment (ATE) and troubleshooting tools such as DMMs designed to detect hard faults (open circuits or shorted circuits)

Engine Harnesses with Interface Box and PIFD

AH-64 Apache Harnesses Connected to Interface Test Adapter Box

Results:

- Left (Cable ID: W185) – AutoMap™ completed

- Right (Cable ID: W186) – AutoMap™ completed – found two additional connections different than Left (Cable ID: W185)

- Connection #1 was J121 Pin 4 to J121 Pin 10

- Connection #2 was shield on J21

- Left (Cable ID: W185) – Continuity failed due to additional connections as described above

- Left (Cable ID: W185) – Intermittence test passed – certified intermittent free

- Right (Cable ID: W186) – Continuity passed

- Right (Cable ID: W186) – Intermittence failed on J39 2,3,4, and shield

- Lock ring had been overtightened causing poor engagement

Engine Harness Intermittence Graphic

Fault Isolation Graphic displaying Intermittence on Connector J39 Wires 2, 3, 4 and Shield

- Right (Cable ID: W186) – Intermittence failed on J39 2,3,4, and shield (cont.)

- No Fault Found (NFF) Cycle Begins as harness passed continuity

- Harness would have been installed on AH-64 Apache

- Operational Conditions → intermittent in flight → operational failure

- Pass continuity on the ground = No Evidence of Failure (NEOF)

- No Fault Found (NFF) Cycle Begins as harness passed continuity

Right (Cable ID: W186) Lock Ring Overtightened Caused Intermittence

Results:

- Right Black Engine Harness (Cable ID: W186) would have been installed on aircraft and would have experienced an operational failure

- Intermittent Fault Detection technology detected and isolated the faults and prevented the NFF cycle

Recommendations:

- Based on Ft. Campbell CONOPS, it is recommended that all AH-64 Black Engine Harnesses be quality inspected with IFD prior to install

- Expand IFD testing to additional AH-64 EWIS